Within many maintenance departments plant configuration and information management is not a dedicated field of expertise and therefore gets little attention. Consequence is a loss of information and hence knowledge of the installations.

Knowledge degradation already occurs when information for a new project is transferred from the supplier to the owner, resulting in gaps in the plant information. Moreover, shortcomings will increase with the age of the installation due to the implementation of all kinds of modifications that are not being registered.

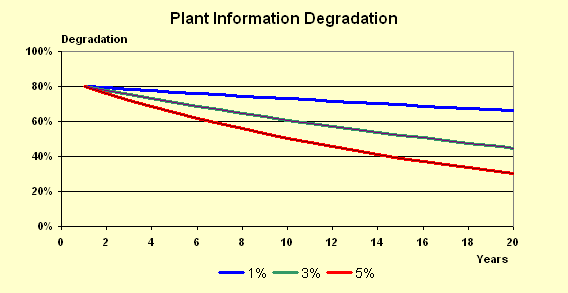

Based on our experience the plant information provided with new production devices are never complete and correct, deficiencies can be up to 40%. The figure shows the information degradation of an installation indicating three different management scenarios. In this case it is assumed that 80% of the actual delivered information is complete and correct. Depending on the quality of the organisation’s configuration and information management three different scenarios are shown, assuming an information degradation of 1, 3, and 5%.

The consequences of incorrect information, lack of information or inability to find information are not visible to the organisation and result in:

- Loss of knowledge of the installation and maintenance practice

- Loss of time during the preparation and execution of maintenance

- Additional failures by using wrong parts, wrong installation of parts or improper adjustments

- Increased maintenance costs

- Increased downtimes

CURE is convinced that complete, reliable and accessible plant information and documentation provides an essential contribution to the safety, maintenance efficiency and knowledge preservation of production installations. Not only with the regular maintenance activities but certainly also with the execution of new projects.